March 1930 Radio News

[Table

of Contents] [Table

of Contents]

Wax nostalgic about and learn from the history of early

electronics. See articles from

Radio & Television News, published 1919-1959. All copyrights hereby

acknowledged.

|

Some of the earliest television

display schemes were mechanically scanned light projection systems rather than electronically

raster scanned cathode ray tubes. This 1930 vintage article from Radio News

magazine reports on a scheme developed by Arthur Watson whereby a specially formed

rotating Monel*

disk served as the rotating reflecting surface to produce the light scanning action.

This invention was hailed as a breakthrough that would finally make commercial TV

available to the masses. Mechanical televisions worked by transmitting scanned

images of the original subject in the form of amplitude modulated electrical signals

whose voltage was determined by the level of reflected light. A synchronizing signal

was included in the transmitted data stream. The scan disk on the receiving end

rotated at the same rate as the transmitter scanning disk, and an electric lamp's

brightness was varied according to the signal's picture voltage level. As you might

guess, the result was very crude, but it was a first step and did produce a useable

televised image. Shortly thereafter, practical electronic scan systems were developed

that eventually won out as the preferred television transmit/receive scheme.

* Monel is a metal alloy of nickel and copper, used for dog tags in WWI

and WWII.

Television Forges Ahead

Photo © The Chicago Daily News

Arthur H. Watson holding the new scanning disc which he invented

and which may hasten the time when television will be available to everyone

New type of scanning disc embodies features which make it adaptable to any transmitting

system now in use.

By Kenneth A. Hathaway

Television development has been given new impetus by the invention of another

type of scanning disc for use in receiving sets, the first account of which appeared

recently in the Chicago Daily News.

The new disc is one of the most flexible that thus far has been developed, in

that it can be adapted to any known system of scanning that is in use at the present

time in experimental work.

It operates on the principle of reflecting light to the screen instead of projecting

it through holes in the disc - a principle which in itself is not new, although

the method by which the effect is obtained is original with the inventor, Arthur

H. Watson, who heads the Watson Television Laboratories of Chicago.

The design lends itself to manufacture with ease, since there are no adjustments

to be made once the disc has been assembled. The reflecting surface is made of highly-polished

Monel metal. Although several types of reflectors have been tried nothing better

has been found. The metal was well known during the war when it was used to make

unbreakable mirrors for the troops. As applied to the television disc, Monel metal

has the property of retaining luster, and it can be bent to fairly sharp angles

without injury. Reference to the illustrations will show that the segments of the

disc protrude at an angle nearing that of ninety degrees.

The complete disc is about seven inches in diameter, a qualification that permits

the use of a comparatively small receiving unit. Aside from the screws that are

used to hold the assembly together, the disc can be made of four parts: the Monel

disc, and a base ring which carries the bearing, and to which is attached a ring

molded in such a way that each of the segments on the metal disc will be given a

definite angle. In order that the segments will be held rigidly in position a complementary

ring is fastened to the base, and as it is clamped into position each of the segments

takes the proper angle as determined from the experiments conducted in the laboratory.

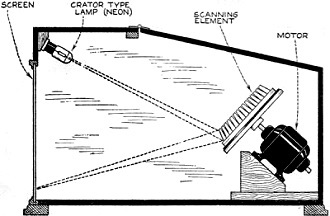

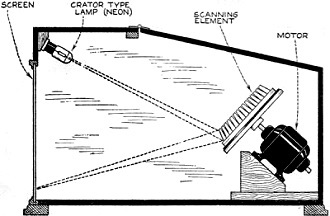

Cross-sectional view of the Watson television receiver, showing

how the mirrors on the rotating scanning disc reflect light from the crator type

neon lamp to the screen, which may be five by six inches square

Details of the scanning disc, showing how the reflecting mirrors

of highly polished Monel metal are bent to the proper angle

The mounting of the disc is determined by the method used by the station transmitting

the television impulses. Although attempts have been made to standardize the television

branch of the radio industry, there seems to be no logical way in which the methods

can be entirely standardized at the present time. Therefore, we find that different

laboratories scan the image horizontally or vertically. In most of the methods the

scanning line describes an arc, although the position of the arc differs. The ends

of the segment may be at the top or the bottom. Regardless of the position, the

Watson disc can be changed to conform to the transmitting system by merely varying

the angle at which the disc is mounted.

The size of the scanning element employed is seven inches in diameter overall

and one and three-quarters inches in depth. The picture produced with this element,

with the screen at a distance of fourteen inches, is as large in area as the scanning

element itself, measuring approximately five by six inches. No lenses or optical

reflection or refraction devices are used other than the segmental elements of the

scanning device itself. An entire receiver may be housed within a cabinet nine inches

wide, fifteen inches high and eighteen inches in length.

Fig. 3 shows the scanning element, consisting of an annulus of Monel metal,

and having inwardly extending radial slots separating the annulus at its inner periphery

into as many segments as there shall be lines to the picture. This annulus is then

cupped to a curvature on a radius of substantially 366 millimeters, and its concave

face subjected to a single grinding and polishing operation, thus producing forty-eight

perfect and identical optically correct focusing reflectors.

Next, the segments are struck upwardly by die to an angle of substantially forty-five

degrees from the axis of rotation, being the central axis of the annulus. The annulus

thus prepared is mounted upon a Bakelite mounting disc, and by the use of a pair

of complementary retaining rings the annulus is drawn tightly in engagement with

the disc. Constantly changing inclination on the opposed surface of the retaining

rings securely locks the segments to their proper adjusted and operable positions

so that the optical axes of the segments diverge outwardly, each adjoining axis

slightly higher or lower as the case may be. A lamp of the crator type is placed

so that the image of its incandescent gaseous part is projected upon the screen

S, and when the scanning annulus is rotated a succession of parallel lines traverses

the screen.

This system of scanning differs from any of the present known scanning systems,

in that the exact shape and size of the spot traversing the screen is determined

with great accuracy by the use of a mask associated with the lamp. Formerly a scanning

spot of peculiar shape devised as most efficient could be obtained only through

the use of a special die for stamping the holes in the spiral disc, which might

be expected to result in difficulties arising through the wearing of the die, not

to mention the high cost of the apparatus necessary for construction.

|

Fig. 3 - Side view of the scanning disc, showing its assembly

of the rings and Monel metal mirror segments

|

Salient Features of the Watson System

Pictures five by six inches may be produced directly on the screen without any

intervening means for the purpose of magnification.

It may be instantly adapted to any type of television scanning systems in use

today, an advantage not possessed by any other known system.

No lenses or optical reflection or refraction devices are used other than the

highly polished reflecting elements of the disc itself.

An entire receiving machine may be housed within a cabinet nine inches wide,

fifteen inches high and eighteen inches in length, and these proportions may be

still further reduced if desired,

The complete televisor comprises but four parts, the lamp, the drum, a motor

for driving the drum and a screen.

The problem of synchronization is taken care of in metropolitan areas by using

a synchronous motor, and swinging the entire motor and drum along the axis of the

drum to adjust for phase position between the poles of the motor, the major adjustment

being carried out by momentarily breaking the motor circuit, permitting lag to take

place. For intra-area reception a variable speed motor may be employed.

During the months in which Mr. Watson has been developing his disc he has tried

other types of reflecting material. Nickel-plating was one of the methods tried,

but nickel-plating fails to hold its luster when exposed to the atmosphere and requires

frequent polishing.

The extensive use of chromium plating appeared to present another possibility,

but it was discarded when it was found that imperfections in the metal would show

through the plating in the form of pockmarks. The marks would not be apparent to

the eye, but when the light was reflected upon the screen they were very much in

evidence. Using chromium plating over a layer of nickel failed to serve the purpose,

for the imperfections in the surface of the metal were made evident through the

double plating.

Accordingly, the inventor reverted to Monel metal, which reflects with nearly

the same efficiency as silvered glass. At the same time the metal is lighter and

more serviceable.

Posted May 27, 2022

(updated from original post

on 3/27/2014)

Color and Monochrome (B&W) Television

Articles

|