|

October 1953 Radio-Electronics

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

After getting out of the U.S. Air Force

in 1982, I was fortunate to get a job at the Oceanic Division of Westinghouse Electric

Corporation in Annapolis, Maryland. Most of the guys who worked in the area with

me were former electronics technicians from the armed forces. We spent most of our

days (and often evenings) building small quantity specialty systems for the U.S. Navy.

The facility was fairly small and was not set up for high volume production; that

was the purview of the much larger operation based adjacent to the Baltimore / Washington

International Airport (BWI),

which built ground-based and airborne radar systems. Whilst there, I did a lot of

wire-wrap assemblies that went into MIL-SPEC systems, primarily rack-mounted equipment

in helicopters and aboard ships deploying towed sonar systems. As such, I received

extensive training for performing soldering, wire-wrapping, electrical contact crimping,

cable harness lashing, and other related skills - including how to unsolder and

unwire-wrap. The initial certification course was two or three weeks long, with

annual proficiency classes. During the class, we were given some background into

wire-wrapping including how the wire-post interface is considered to be gas-tight,

vibration-proof, and is very low resistance. Here is the 2012 version of

MIL-STD-1130C, CONNECTIONS, ELECTRICAL,

SOLDERLESS WRAPPED, where you can see what is required. The on-site Navy inspectors

examined each connection using a magnifier. If the number of turns was too low,

or the amount of slack between posts was too small, or there was a nick in a wire's

insulation, or a post had too much surface contamination, or any of a host of other

things was violated, we'd get a failure and had to re-work it. The boss was not

happy when that occurred. This same ad ran in the October 1953 issue of

Radio & Television News. After getting out of the U.S. Air Force

in 1982, I was fortunate to get a job at the Oceanic Division of Westinghouse Electric

Corporation in Annapolis, Maryland. Most of the guys who worked in the area with

me were former electronics technicians from the armed forces. We spent most of our

days (and often evenings) building small quantity specialty systems for the U.S. Navy.

The facility was fairly small and was not set up for high volume production; that

was the purview of the much larger operation based adjacent to the Baltimore / Washington

International Airport (BWI),

which built ground-based and airborne radar systems. Whilst there, I did a lot of

wire-wrap assemblies that went into MIL-SPEC systems, primarily rack-mounted equipment

in helicopters and aboard ships deploying towed sonar systems. As such, I received

extensive training for performing soldering, wire-wrapping, electrical contact crimping,

cable harness lashing, and other related skills - including how to unsolder and

unwire-wrap. The initial certification course was two or three weeks long, with

annual proficiency classes. During the class, we were given some background into

wire-wrapping including how the wire-post interface is considered to be gas-tight,

vibration-proof, and is very low resistance. Here is the 2012 version of

MIL-STD-1130C, CONNECTIONS, ELECTRICAL,

SOLDERLESS WRAPPED, where you can see what is required. The on-site Navy inspectors

examined each connection using a magnifier. If the number of turns was too low,

or the amount of slack between posts was too small, or there was a nick in a wire's

insulation, or a post had too much surface contamination, or any of a host of other

things was violated, we'd get a failure and had to re-work it. The boss was not

happy when that occurred. This same ad ran in the October 1953 issue of

Radio & Television News.

| Bell Telephone

Laboratories Infomercials |

|

|

|

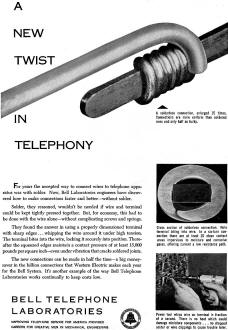

Bell Telephone Laboratories - A New Twist in Telephony

A solderless connection, enlarged 15 times.

Connections are more uniform than soldered ones and only half as bulky. A solderless connection, enlarged 15 times.

Connections are more uniform than soldered ones and only half as bulky.

For years the accepted way to connect wires to telephone apparatus was with solder.

Now, Bell Laboratories engineers have discovered how to make connections faster

and better - without solder.

Solder, they reasoned, wouldn't be needed if wire and terminal could be kept

tightly pressed together. But, for economy, this had to be done with the wire alone

- without complicating screws and springs.

They found the answer in using a properly dimensioned terminal with sharp edges

... whipping the wire around it under high tension. The terminal bites into the

wire, locking it securely into position. Thereafter the squeezed edges maintain

a contact pressure of at least 15,000 pounds per square inch - even under vibration

that cracks soldered joints.

The new connections can be made in half the time - a big money-saver in the billion

connections that Western Electric makes each year for the Bell System. It's another

example of the way Bell Telephone Laboratories works continually to keep costs low.

Bell Telephone Laboratories

Improving Telephone Service for America Provides Careers for Creative men in

Mechanical Engineering

Cross section of solderless connection. Note terminal biting into wire. In a

six-turn connection there are at least 20 clean contact areas impervious to moisture

and corrosive gases, offering current a low resistance path.

Power tool whips wire on terminal in fraction of a second. There is no heat which

could damage miniature components ... no dropped solder or wire clippings to cause

trouble later.

Posted November 10, 2020

|