|

For some reason the

"too clever by half"

saying (but not in an insulting way) comes to mind when reading this article about

color TV from a 1951 issue of Radio & Television News magazine. The

color television industry was still searching for an acceptable standard broadcast

format when this was written, and the electromechanical contraption was not considered

too elaborate considering the original color TV schemes were all a conglomeration

of whirling colored wheels, light sources, and photodetectors coupled with accommodating

timing and intensity signals (see the articles listed at the bottom of the page).

Because there was not agreement on what the final commercial broadcast signal format

would look like, there was not a lot of motivation for test equipment makers to

invest time and money into providing gear for research and development laboratories.

CBS (Columbia Broadcasting System)

and NBC (National Broadcasting Company)

were the two primary competitors, each with their own standard.

Do you remember the ads for the screen that

installed on the front of a TV set to convert black and white (B&W) to color?

It had green at the bottom to color the grass, red in the center, and blue like

the sky at the top (see image at right). No, I never bought one. Do you remember the ads for the screen that

installed on the front of a TV set to convert black and white (B&W) to color?

It had green at the bottom to color the grass, red in the center, and blue like

the sky at the top (see image at right). No, I never bought one.

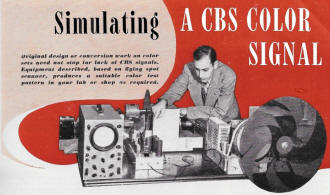

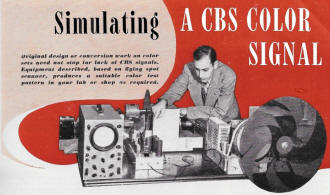

Simulating a CBS Color Signal

Original design or conversion work on color sets need not stop

for lack of CBS signals. Equipment described, based on flying spot scanner, produces

a suitable color test pattern in your lab or shop as required.

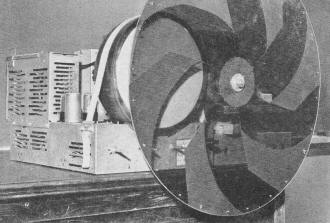

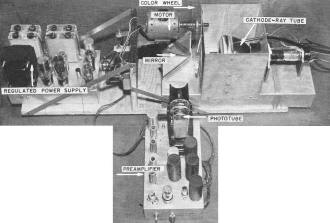

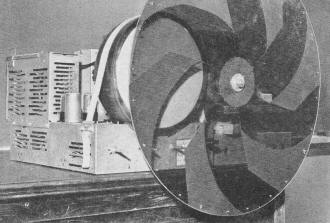

Fig. 1 - Complete set-up of equipment used in color demonstration

presented at the Radio Electronics School of New York.

By Murray Barlowe

Color Development Eng., Tele-King Television Corp.

The decision by the FCC to adopt the CBS color system was the spark that set

off the biggest controversy that the radio-television field has experienced in years.

An overwhelming demand for information about color television, both by the public

and the technician, resulted. It was in response to this demand that the author,

with the full cooperation of the staff of the Radio Electronics School, set up a

series of public demonstrations and lectures on color television.

Since CBS was not transmitting color signals at the time, the problem was solved

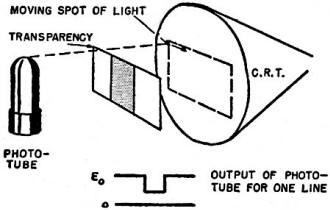

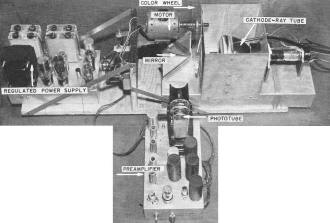

by constructing a "flying spot scanner" (Fig. 8) to take the place of the color

camera.

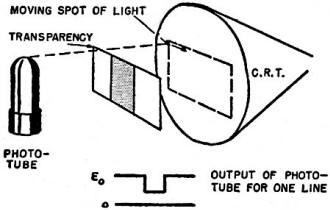

Basically, the equipment consists of a high intensity CRT with its associated

high voltage power supply and deflection circuits, a photoelectric pick-up tube,

and a high gain video amplifier. The picture to be transmitted is in the form of

a transparency which is placed on the face of the CRT. The raster on the face of

the CRT is produced by a rapidly moving spot of light. At anyone instant, only one

spot on the face of the CRT is giving off light. This spot of light passes through

the transparency and falls on the photoelectric pickup tube. The phototube converts

the light into an electrical voltage proportional to the intensity of the light.

As the spot of light moves across the tube, the amount reaching the phototube will

increase or decrease, depending upon the density of the different parts of the transparency.

Fig. 2 - Intensity of the light from the moving spot, impinging

on phototube varies with any change in transparency density.

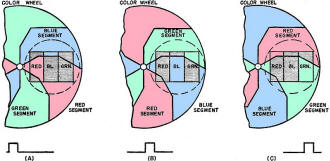

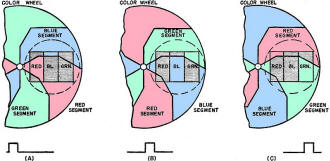

Fig. 3 - To obtain color signal, a color transparency and disc

are inserted as shown.

Editor's Note: This set-up was originally used as a closed-circuit

system for demonstrating color television. From the ideas presented it is possible

for manufacturers or service organizations who are doing work on color receivers

to build a test unit so that work can continue even in the absence of on-the-air

CBS signals. For additional details on constructing a flying spot scanner, see J.

R. Popkin-Clurman's article "Simplified Ham TV Station" appearing in the May, June,

and July 1950 issues of this magazine.

Fig. 4 - Scanning sequence. Output of phototube is shown in (A)

for red, (B) for blue, and (C) for green. Color disc rotates at a speed of 1440

revolutions per minute.

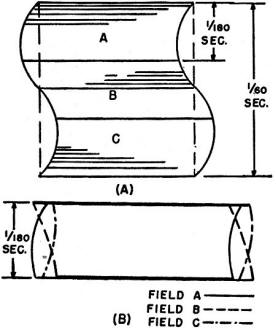

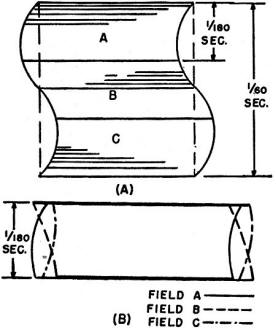

Fig. 5 - Curvature caused by a 60-cycle magnetic field when operating

at 180 field/sec.

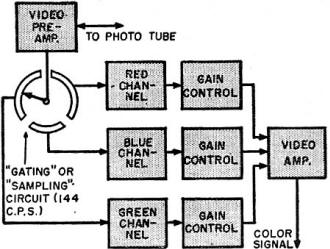

Fig. 6 - Block diagram showing how gated circuit is used to select

the proper channel.

Fig. 9 - An example of the curvature of the vertical edges of

the raster caused by (A) 60 cycle and (B) 120 cycle interference.

Fig. 10 - Provision must be made for rotation of the motor in

order to obtain the proper color phasing at the TV receiver.

As each line is scanned, a voltage is generated by the phototube which varies

in amplitude directly as the light and dark variations on the transparency, Fig.

2. The output of the photo tube is amplified and is the video signal containing

all of the picture information. To adapt this principle to produce a color video

signal, a color transparency is used in place of the black and white transparency

and a color filter wheel is inserted between the transparency and the phototube.

See Fig, 3. A simple color transparency, consisting of three vertical bands of color,

will be used in place of a full color picture in our analysis of how the system

works. As the spot of light moves across the first line from left to right, a section

of the color filter wheel moves between the transparency and the photo tube. Assuming

the first section to be a red filter, which will allow only red light to pass through,

the output of the phototube will increase when the spot of light passes through

the vertical red strip in the beginning of each line, as indicated in Figs. 4A and

4B. Each filter section of the color wheel will be between the transparency and

the photo tube for the time required for the light spot to scan an entire field.

For a color signal co-forming to the CBS standards, this time interval would be

1/144th of a second. During this interval, all of the red portions of a color image

will pass through the color filter and produce a video signal representing the red

image. At the start of the next field, the spot of light will be in the upper left

hand corner and a blue section of the color wheel will now be coming into place.

It will only allow the blue light to pass through and so the video signal produced

during this field will represent the blue image. Next, the green filter comes into

place and the process is repeated, producing the green video signal. In practice,

a full color transparency takes the place of the three vertical color bars and the

video signals produced during each field would have a more complex waveform.

The output of the video amplifier is applied to the grid of the CRT in a TV receiver.

Sync pulses from the sweep circuits of the flying spot scanner are used to synchronize

the sweep circuits of the receiver. During each field a picture is produced on the

face of the CRT which is a black and white version of the primary color image being

scanned at the time. If we look at this black and white image during the red field

through a red filter, we would see a true reproduction of the red information in

the transparency. The red filter tints the black and white image to its correct

color. By using a color filter wheel at the receiver similar to the one at the flying

spot scanner, and having it rotate in synchronism, the full color images are first

separated into their primary colors, transmitted as black and white versions of

the primary colors, tinted by the color wheel at the, receiver, and reproduced in

full color.

In the CBS system, the color fields are scanned at the rate of 144 per second.

A color wheel containing six color filter segments, two each of the three primary

colors, is rotated at a speed of 1440 revolutions per minute by a synchronous motor.

(Since 1440 rpm synchronous motors are not available, an 1800 rpm motor with a 4

to 5 speed reduction is used to obtain the required speed of 1440 rpm.) This is

equivalent to 24 revolutions per second. Since there are six equal segments in the

wheel, the time required for a single segment to pass a given point would be one

sixth of a 24th of a second, or a 1/144th of a second. This is the time required

for a single color field.

By using a horizontal sweep frequency of 29,160 cps, interlaced at 144 fields

per second, a 405 line picture is produced.

Fig. 7 - Over-all view of the color receiver used by author in

his simulated CBS color system. The color wheel consists of twelve segments with

every other segment opaque. The sequence is red color filter, opaque segment, blue

filter, opaque segment, green filter, opaque segment. etc., with a total of six

color filter segments and six opaque segments. In developing the shape of the color

filter segments it was apparent that light from the CRT did not pass through every

part of the wheel but rather through "half moon" shaped areas. Since this was the

case. it was not necessary for the wheel to be entirely transparent. Balance weights

and metal strips used for generating the reference sync pulse were mounted on the

opaque or unused areas. Opaque segments were finally deemed unnecessary and eliminated

on later models.

Fig. 8 - Over-all view of flying spot scanner.

More than the usual amount of power supply filtering was necessary. This is a

problem that technicians making color conversions of transmitting or receiving equipment

will have to contend with. In the present black and white system using 60 fields

per second, hum in the horizontal deflection circuits could cause the vertical sides

of the raster to have a slight curvature as illustrated in Figs. 9A and 9B. This

hum may be due to magnetic fields (60 cycle) from the power transformer or to the

120 cycle ripple due to insufficient filtering in the power supply. This curvature

is hardly noticeable when the vertical sweep frequency is 60 cps, At sweep frequencies

of 144 or 180 per second, the visible effect becomes serious. Figs. 5A and 5B illustrate

the effect (intentionally exaggerated) when the interference is from a 60 cycle

magnetic field and the equipment is operating at 180 fields per second. Three fields

would occur in the time previously required for one field. Superimposing the three

fields, as they would appear on the face of the CRT, it becomes apparent that they

are displaced with respect to each other. This makes it impossible for the three

colors to "register" properly, producing a picture that is constantly shimmering,

and one which has very poor detail.

To keep this from happening it is necessary to thoroughly filter the "B" supply,

and protect the CRT against the influence of stray magnetic fields. A mu-metal shield

around the picture tube and a heavy copper band around the power transformer are

some of the possible solutions to the problem.

Color Balance

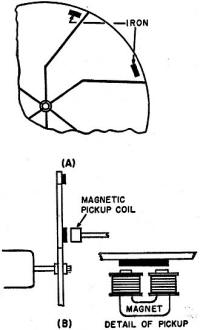

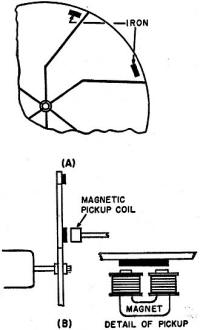

Fig. 11 - Mechanical details of synchronizing system. Six pieces

of soft iron are fastened to outside edge of color disc.

The spectral response of the 931A phototube used as the pickup device drops off

rapidly at the red end of the spectrum. To correct this, a thin sheet of very lightly

tinted red acetate was permanently fastened to the face of the CRT used in the flying

spot scanner. This cut down the intensity of light of the colors other than red

to compensate for the lack of sensitivity of the phototube to red. A better method

might be to use two or more 931A phototubes feeding the video amplifier with a red

color filter permanently mounted in front of one tube thus making it sensitive only

to red light. This would boost the level of the video signal produced by the red

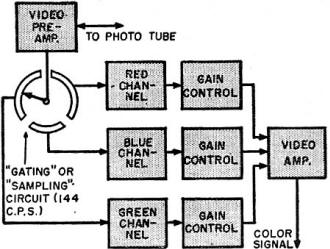

image. Our equipment is presently being modified to include a "gating" circuit operating

at the field frequency which will switch the output of the phototube to a separate

video amplifier every time a different color filter segment of the color wheel comes

into place (Fig. 6). This will connect the video signal out-put of the phototube

to the red video amplifier for the duration of the red field. Immediately after

the red field the signal is switched to the blue video amplifier for the duration

of the blue field, and finally to the green video amplifier for the duration of

the green field. By adjusting the gain of the video amplifier for- each color channel,

the relative amplitudes of the color signals can be properly balanced.

Synchronizing the System

Proper sync and phasing of the complete system is accomplished in the following

manner. Six thin pieces of soft iron are fastened along the outside edge of the

color wheel at the flying spot scanner (Fig. 11). The pickup coil from a magnetic

phonograph pickup is mounted close to the edge of the wheel. As the iron segments

move past the pickup coil, a pulse is produced. Since there is a piece of iron for

every color segment, the output of the pickup coil will be a series of pulses at

the field frequency. These pulses are used to synchronize the vertical sweep circuits

and thereby control the timing of the entire system. A phase shifting network is

connected between the magnetic pickup coil and the vertical sweep generator. By

adjusting this control the start of each field can be varied with respect to the

position of the color wheel. Once set, this control usually doesn't have to be readjusted,

unless the position of the pickup coil is changed.

Color phasing at the receiver is accomplished by mounting the motor which rotates

the color wheel so that it can be rotated through approximately 160 degrees, as

illustrated in Fig. 10. The motor is rotated until the segment of the color test

pattern marked "blue" becomes blue.

Posted August 17, 2020

Color and Monochrome (B&W) Television

Articles

|